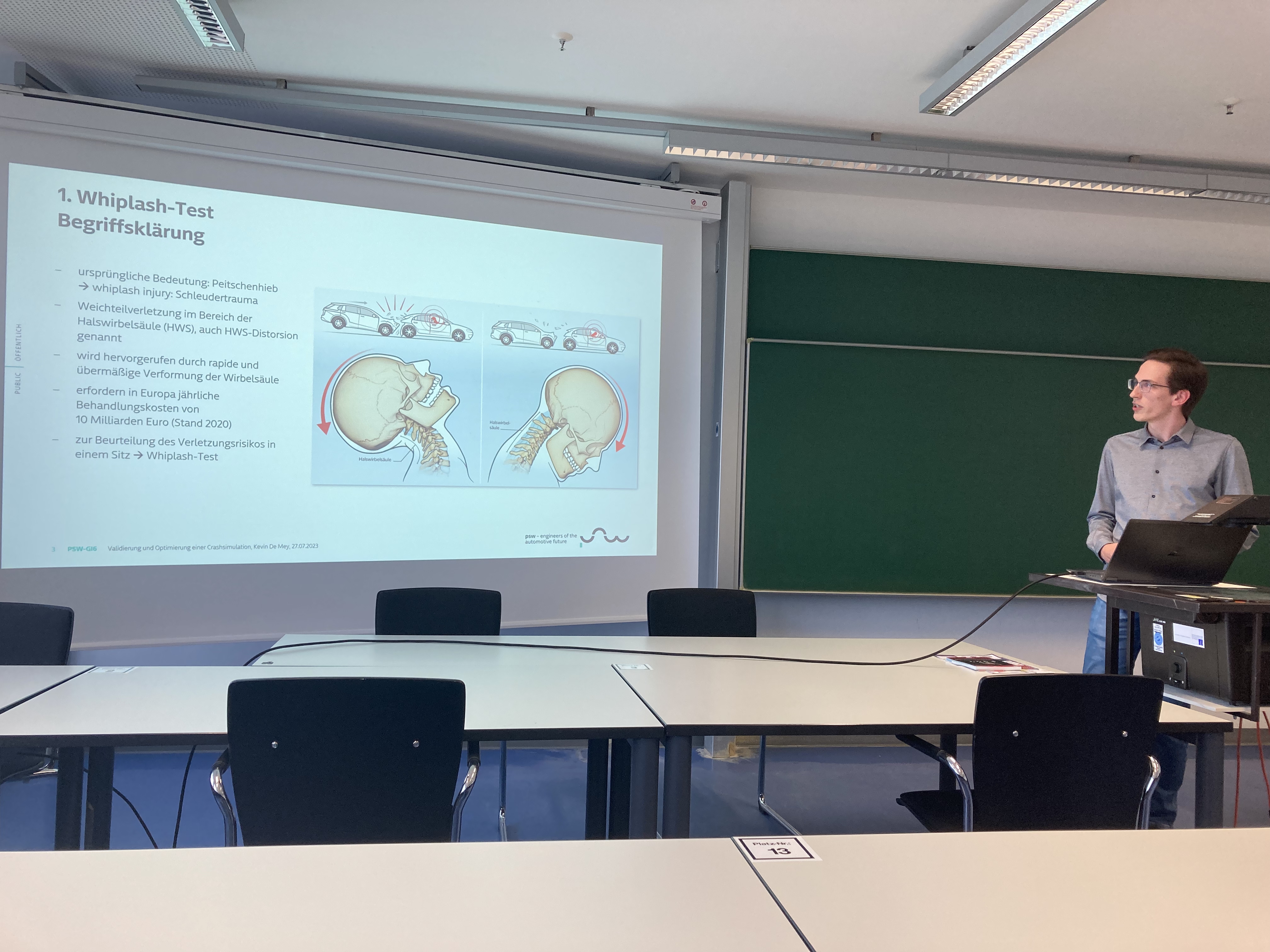

Whiplash injuries in accidents are not only painful but also very expensive to treat. Car seats are a key feature in respect of the risk of injury and play a central role in whiplash tests. A car seat is mounted on a sliding carriage in the whiplash test and is moved at a set rate of acceleration. There is a BioRID-II dummy in the seat which is used to assess the impact of speed increases and forces on the passengers in a rear-end collision. Our colleague Kevin De Mey did his bachelor’s thesis at PSW for which he optimised and validated a crash simulation for a seat by making changes in the design process and the modelling of the seat.

Kevin used the finite element method (FEM) to compare the simulated whiplash test with the real test. “The process involves discrete and virtual methods of breaking a component down into a finite number of smaller elements in order to be able to make computer-based predictions about the physical behaviour of the component,” explained Kevin.

He found differences between the simulated whiplash test and the real whiplash test in various acceleration curves. In a bid to improve the simulation, he started by making changes to the modelling of the seat foams by reducing their complexity, thereby enhancing the mesh quality. This was quick to yield results, leading to a convergence of the test curves.

He also found that the dummy does not have time in the calculation process to adjust properly to the seat. In the real test, quite some time inevitably passes between the positioning of the dummy and the impact of the crash. The seat foam and seat cover will compress during this time, as will the clothes on the dummy. In the calculation, the crash impact occurs immediately after the dummy is put in place. This means that the dummy does not have time in the simulation to end its interaction with the seat. The adjustment of the calculation process gave the dummy the time frame it needed for this process, allowing Kevin to get the results much closer to the real test.

“The results of my bachelor’s thesis are now incorporated into the day-to-day work at PSW,” he said, clearly delighted at the outcome. “The better the simulations are, the more efficient we will be in the vehicle development process.” Kevin has not regretted writing his thesis at PSW, even though there were a few challenges to overcome. “Familiarising myself with the dozens of programs used in the corporate group was very complex at times. But everyone in the department was there to help and advise me with their expert input in both theory and practice,” added Kevin. “I was also really lucky with my supervisor. Martin Nagengast did his master’s thesis on the same subject a few years ago. So he was very knowledgeable and took a lot of time to answer my questions.”

After completing his bachelor’s thesis, Kevin went straight into the Interior Design department at PSW. “I’ve always been fascinated by cars and here I can turn my hobby into a career to some extent. Having done my thesis and worked closely with the others, I had already been shown the ropes and was able to get stuck into the job immediately after graduating. And one of the most important things was knowing that all the people in my department are nice and helpful, which is perfect for starting on the career ladder.”